Paper burger box making machine

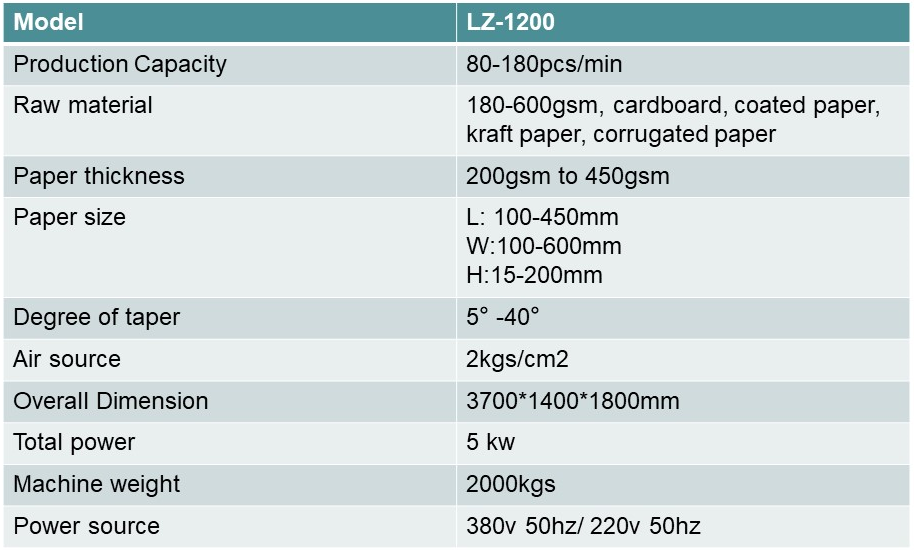

- Model

- LZ-1200D

Item specifics

- speed

- 80~180pcs/min

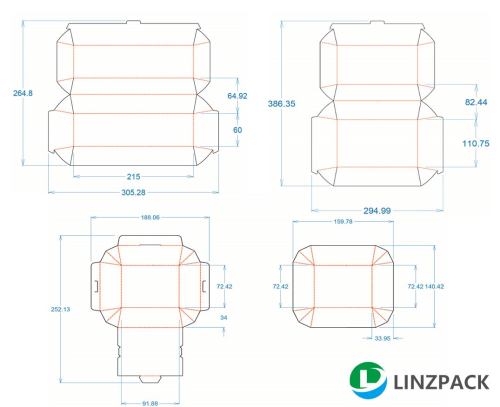

- raw material

- 180~600gsm paper

- paper thickness

- 250~400gsm

- degree of taper

- 5° -40°

Review

Description

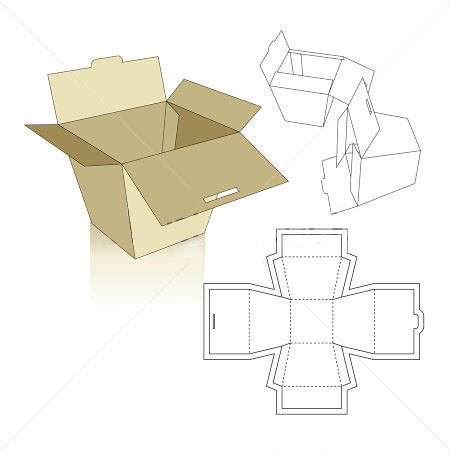

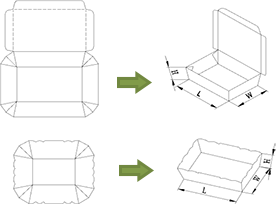

LZ-1200D tray forming machine is used to produce clam shell trays, chip scoops, leak-proof trays, lunch box, on-the-go trays, etc.

It adopts automatic feeding, gluing, erecting and other continuous processes to complete the molding of the product. It is with simple operation but intelligent touch screen .Setting data can be saved.

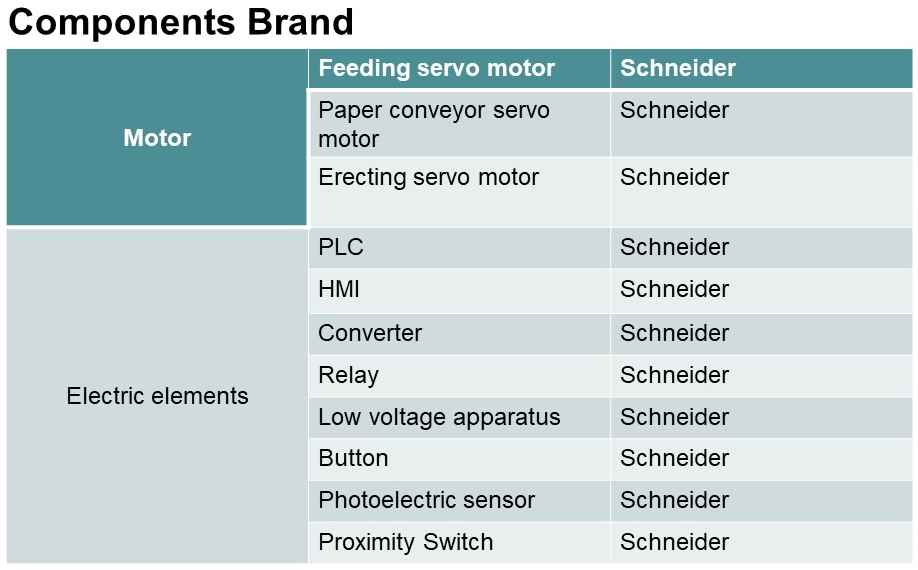

All Schneider brand electronic parts make the whole machine work stable and durable.Precise positioning, smooth running, safety and reliability.

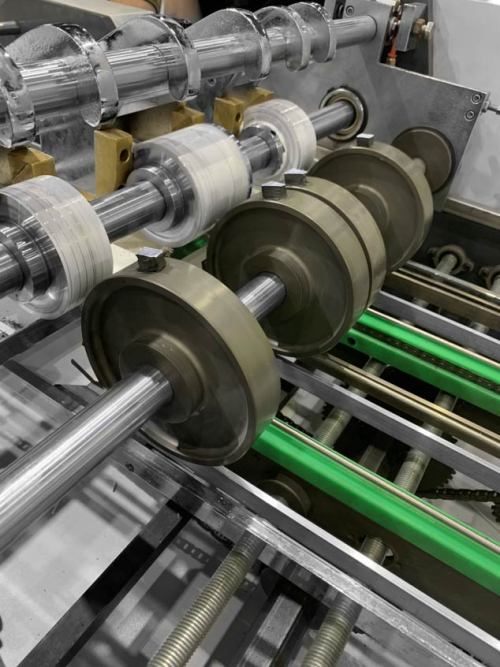

The standard cold gluing unit applies dispersion glue all

over in the required shape on the blanks by means of foam

Pads on gluing wheels.

Also provide the auto glue adding system, make glue adding easy and convenient.

The machine have counting paper equipment,

so that can count product quickly and accurately.

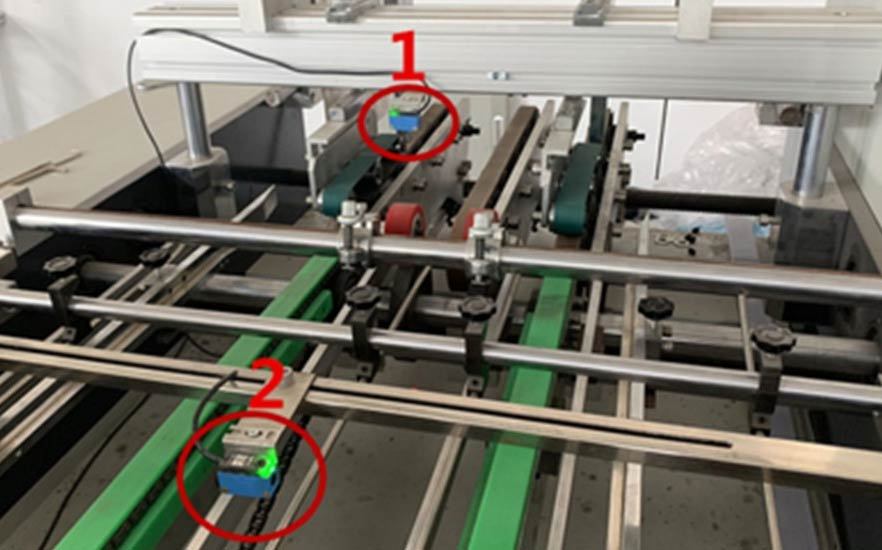

Sensor 1: Paper will stop feeding when it is blocked.

Sensor 2: The paper box and the wheel will separate when paper no feeding.

The whole machine adopts independent servo motor to control each moving part separately, such as the feeding part, conveyor part, and the erecting part, all of them adopts Schneider servo controlled separately. Guarantee the service life of the machine. So we can make sure our machine warranty is 3 years.